It was significantly colder today. Both of us wore long pants and I had the hoodie on to ward off the cool weather. Undeterred by the entirely expected drizzling rain and north-easterly winds, Chris and I move our attention to the bulkheads.

We used the floor of the 20’ container to layout the wooden pieces that required gluing. Chris had gone ahead and chalked out the outlines on each board to ensure that we were able to fit the pieces together appropriately. This is another great example of the difference between Chris and I – he is a “measure a thousand times and cut once”, while I’m more of a “I’m bored already lets crack on” kind of guy.

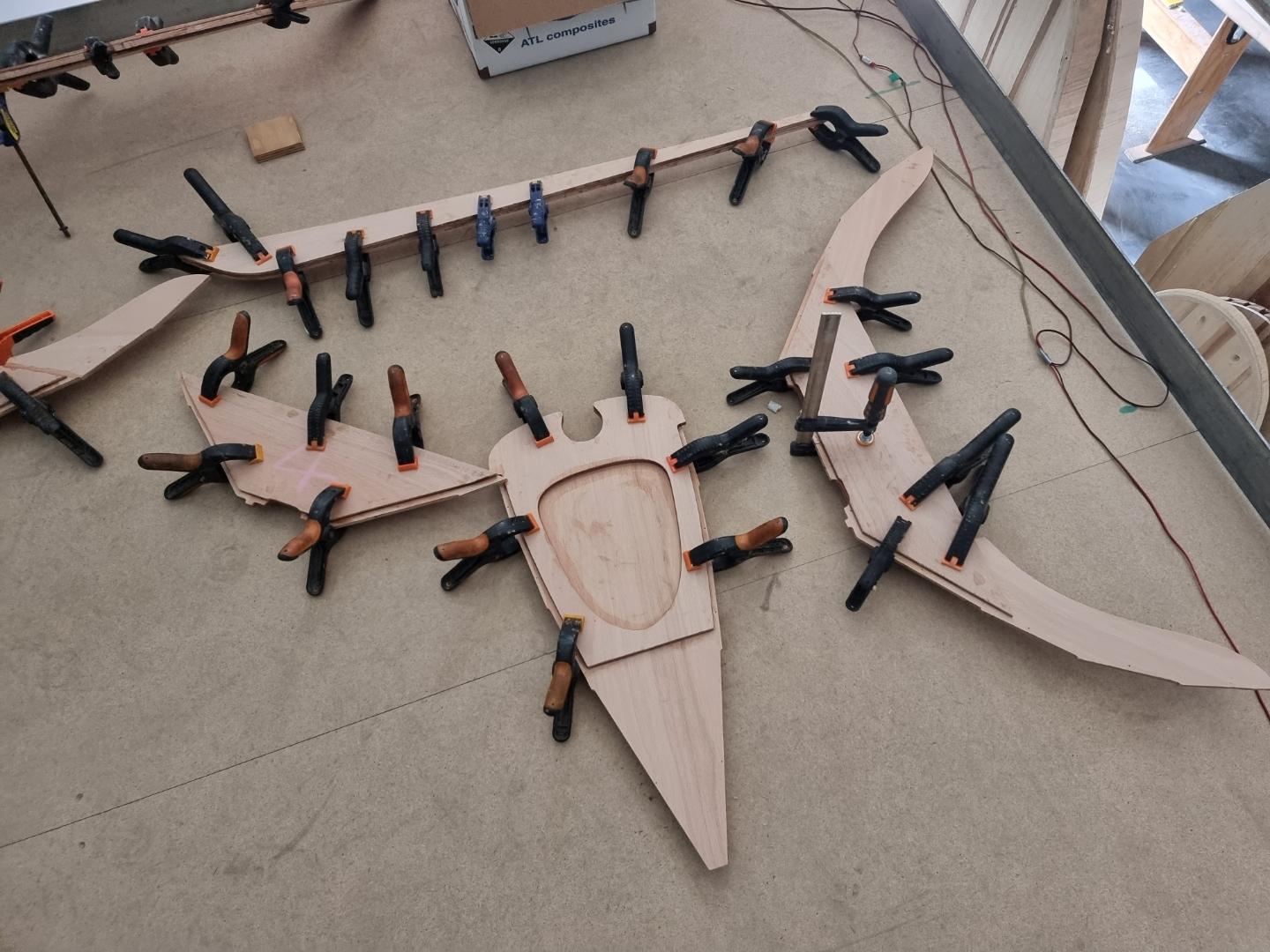

Once the pieces were laid out with clamps ready to go, I went ahead and mixed 100g of epoxy with a few spoons of microfibre blend to thicken the mix and then added the hardener / catalyst. Chris then painted the resin onto the boards while I followed behind and clamped the pieces together. Definitely a good idea to work as a pair on this.

The smaller amount of resin was easy to work with but wasn’t enough. That problem was easily rectified by mixing another batch (same amount as before) in a new container and finishing the job. The containers we used this time were more like ice cream containers rather than the thin takeaway containers we used before. The thicker plastic allowed us later to easily remove the dried resin and reuse the container. The thinner takeaway containers become very brittle and were really only suitable for one application.

The day was successful as the bulkheads were now all glued together. Both Chris and I continue to find the simple manual processes involved incredibly cathartic. It’s a form of mindfulness where you need to concentrate on what you’re doing but its not destroying you brain. Likewise the labour is light and rewarding.

So Day Five done after a fruitful few hours of work. Next steps will be more sanding and dry fitting the bulkheads and the side panels together.